中文

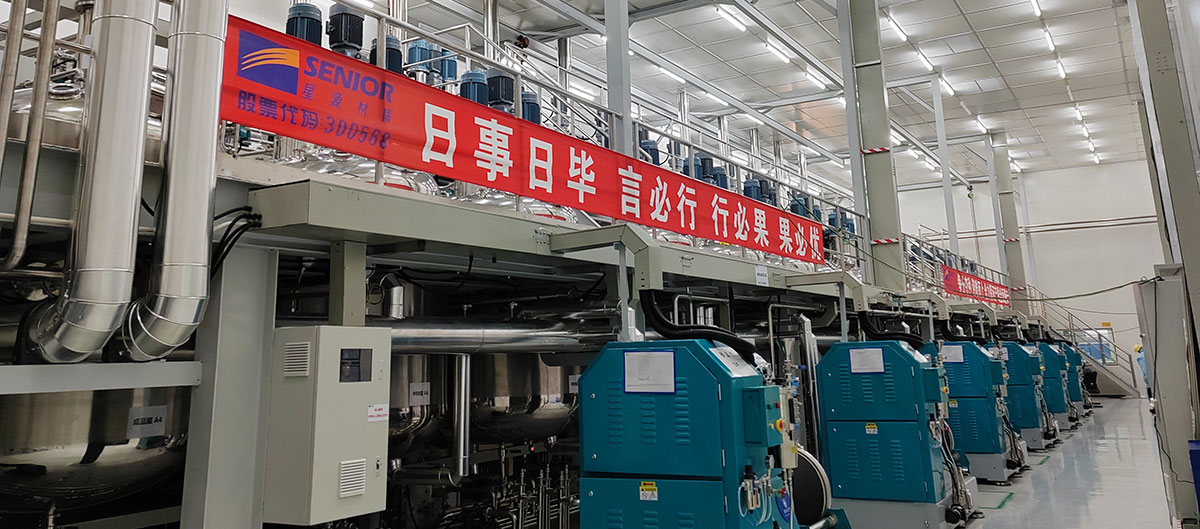

Purification and Decoration Project of Nantong Xingyuan High Performance Lithium ion Battery Wet Process Diaphragm and Coated Diaphragm (Phase I)

Construction period: April 2022 January 2024

Building area: 226000 m²

Clean area: 120000 m²

Contracting mode: Mechanical and Electrical Contracting

Service content: Purification decoration, electrical, piping, HVAC, self-control

Product: High performance power lithium battery wet separator, coated separator

Industry value: Nantong Xingyuan is another new base for Xingyuan Material Company's layout in China, with an estimated investment of 10 billion yuan and a land area of 500000 square meters. The production line includes 16 wet process lines and 100 coating lines, with an expected annual output of 3 billion square meters of wet process membranes and coated membranes, enabling rapid expansion of production capacity.

Milestone significance: The cooperation between China Electronics Second Company and Xingyuan Material Company has been elevated, and the original cooperation content has been expanded from only mechanical and electrical purification construction to design+mechanical and electrical purification, laying the foundation for the subsequent EPC cooperation mode.

Project highlight 1. During bidding, project planning is done well, and after the bid is awarded, personnel immediately enter the site;

2. Summarize the experience of the Changzhou Xingyuan project, develop a reliable construction plan and a reasonable sequence of process connections based on the characteristics of wet mainline reverse construction;

3. The power station adopts an assembled modular installation method, actively confirms parameters, determines the processing drawings in advance, assembles and automatically welds in the processing plant, and after completion, transports to the power station for direct assembly.

Aerial view

Pulp making area

Coating line

Prefabricated module for power station

Private room

Power distribution room

400 892 1298

苏ICP备15056857号-1 Enterprise Post Office

COPYRIGHT©ALLRIGHTSRESERVED.China Electronics System Engineering No. 2 Construction Co., Ltd.

Business Scope

Corporate Culture

Party Building